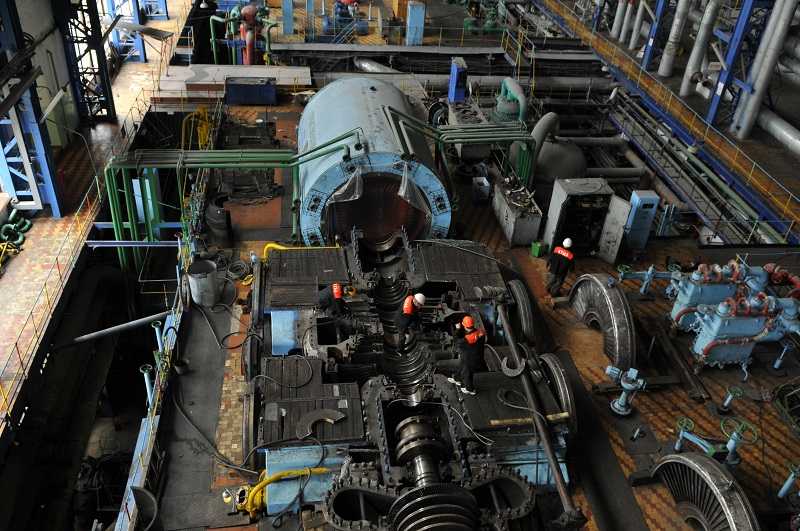

Throughout production activity, the plant has completed more than 250 overhauls and more than 550 midlife and current repairs of steam turbines.

The staff consists of highly qualified specialists to carry out work at the station who have great experience in energy sector and is provided with all necessary equipment, mainly of our own production.

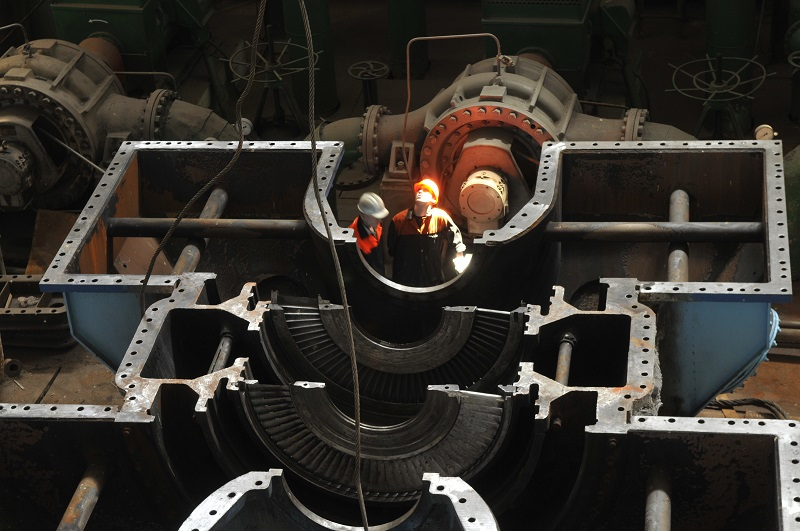

To ensure high quality work, the plant uses a combined turbine unit repair scheme, which performs a part of work by using industrial-factory method at the production base in Qaragandy (for the most critical turbine components). In these cases we use test benches, special metalworking machines, special equipment, balancing machines, diagnostic and instrumentation. Turbine rotors, components of control and steam distribution systems, turbine sliding bearings, housing parts and heat exchangers are more often repaired at the production base, reblading of turbine rotor impellers and turbine component modernization are performed as well.

Main types of work performed during overhauls, midlife and current repairs:

- We perform all types of steam turbine turnkey repairs up to 500 MW, including reblading at all stages, rotor repair with removal and installation of mounted parts, cylinder and bearing housing dismantling and installation.

Nearly 50% of turbine and turbogenerator overhauls are carried out by our company on a turnkey basis, including repairs of all auxiliary turbine equipment, standard and specialized repairs of turbogenerators and total setup. More than 20% of turbine repairs were carried out with modernization of certain components and turbine systems, which allowed to improve reliability, quality and turbine efficiency.

- Technical upgrading (modernization, renovation) of turnkey turbine units during overhauls.

- Carrying out emergency repairs on basic and auxiliary power equipment by highly qualified personnel and a mobile mechanical repair shop. Mobile mechanical repair shop provides the following types of work: turning; milling; drilling; sharpening; locksmith.

- Drive turbine repair.

- Turbine department’s auxiliary equipment repair .

- Inspection, repair, service and maintenance of control and steam distribution systems.

- Modernization of certain components and elements of control, protection and steam distribution systems.

- Turbine and pump bearing shell relining, machining, grinding in spheres.

- Boring (ribbing) of holes in the rotor coupling halves. Hole boring is carried out by the devices of our own production.

- Restoration of spring coupling performance of Bibi turbines PT-60-90 (130), modernization of these couplings by manufacturing all newly installed parts and organization of individual oil supply to each coupling half. Coupling modernization is carried out to increase vibration reliability, maintainability and coupling’s clutch life.

- Pump repair.

- Compressor repair.

- Repair and manufacture of heat exchangers.

- Flow path laser alignment.

- Manufacturing of spare parts for power equipment.