The general purpose of the electrohydraulic control system (EHDS) is to ensure reliable, continuous and high-quality control and regulation of turbine operation in all operating modes permitted by technical conditions, as well as in emergency situations.

EHDS is designed to control the rotation speed of the turbine rotor during starts, stops and synchronization of the generator with the network, control the power of the turbogenerator, control the steam pressure in the production and heating extraction of the turbine, as well as the temperature of the network water, and implement protective functions.

EHDS produced by QTMP is manufactured as a self-sufficient and maximally autonomous system with high operational readiness. EHDS is equipped with a duplicated turbine controller operating on the “hot” standby principle, which implements all regulation and protection functions. The high availability factor of the EHDS, the absence of deterioration of characteristics over time and the need for repeated settings, make the system always ready for operation, despite any downtime.

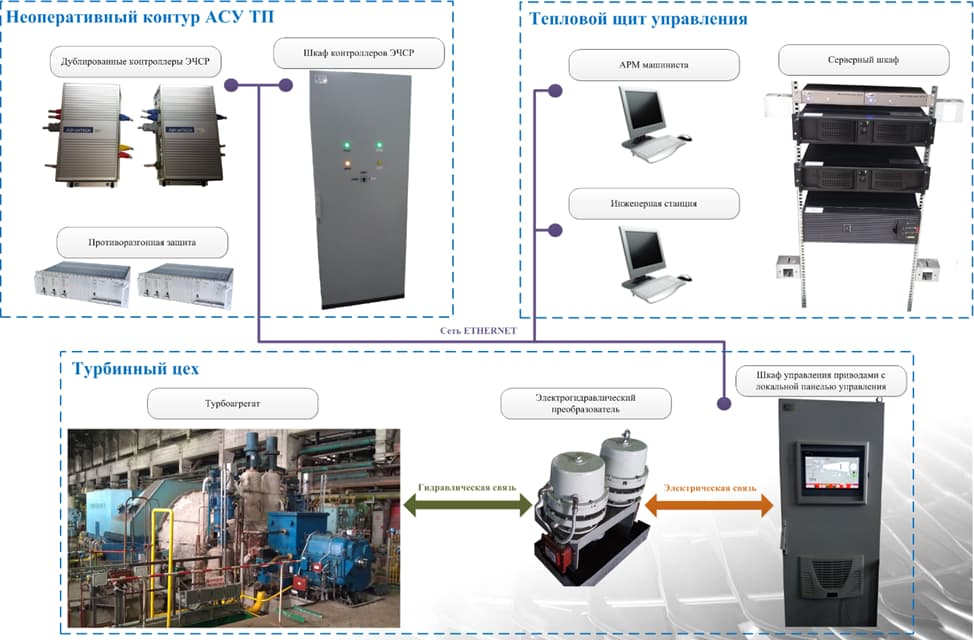

Control of turbine parameters is provided both from a “local” control cabinet located next to the turbine in the turbine shop and from an automated workstation (AWS) located on the thermal control panel.

The function of archiving the necessary turbine parameters has been implemented. Also, EHDS can be integrated into the existing control system of the station.

Drawing. Functional diagram of EHDS.

Main components of the EHDS:

1. Hydraulic part of the control system (servomotors, rotary diaphragms). Designed to move control valves and rotary diaphragms using servomotors, as well as timely closing of the servomotors in the event of activation of hydraulic protective devices.

2. Electrohydraulic part of the control system (electrohydraulic EGP converters). An intermediate converter link in the circuit for transmitting control signals from the turbine controller to the hydraulic part for controlling the servomotors of control valves and rotary diaphragms.

3. Electrical part of the control system. Performs measurements of the main parameters of the turbine control system. With the help of a turbine controller, its state is analyzed and control signals are generated for regulation and anti-overclocking protection.