All turbines equipped with EHDS manufactured by QTMP LLP have the ability to regulate the active power of a separate turbogenerator with an accuracy of up to 0.5 MW, which meets modern requirements of the electricity market and demonstrates an increase in the quality of generated energy.

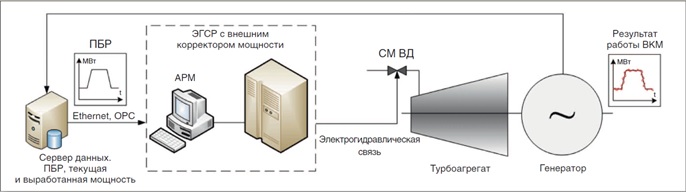

To ensure high-quality regulation of the total electrical power of the station, we offer an add-on tool for the power regulator, developed according to a project with the working title “VKM” (External Power Corrector), which is supplied as a module for the EHDS turbine controller of our production.

This project has already been implemented at the leading power plants of Tatarstan, where to date we have modernized 38 turbines of various capacities.

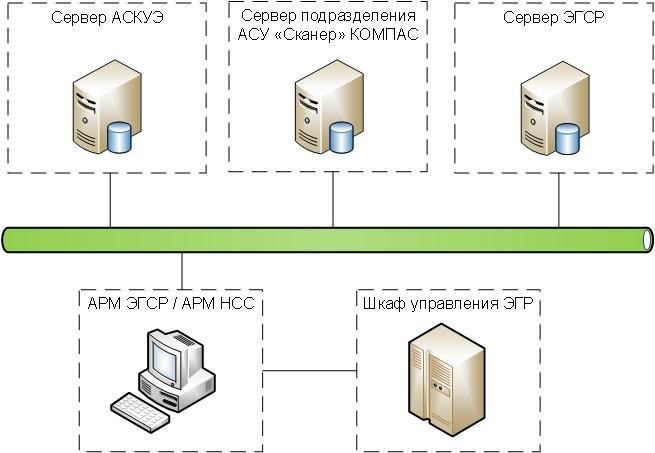

The essence of the VKM project is to ensure dynamic correction of the generated power of each power plant and the regional energy system as a whole, in accordance with the planned target, through dedicated turbogenerators. To solve this problem, communication with the telemechanics devices of the thermal power plant and with the ASKUE is required.

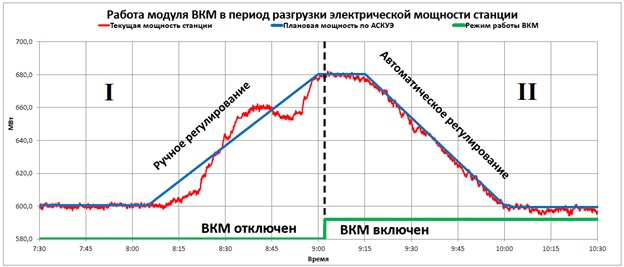

The module implements a regulator with a power deviation correction algorithm. The module also has a protective function of automatic shutdown when the established limits for deviations in the network frequency or turbine rotor speed are exceeded, operating in watchdog mode.

The declared accuracy of plant power regulation, which is the deviation at the end of the hour, after the introduction of VCM is less than 0.5 MW/hour.

Operation of the module in automatic mode allows the station to participate in automatic system regulation, improve the economic performance of the power plant, prevents overconsumption of standard fuel in case of excess electricity generation and prevents underproduction of electricity.

In general, the implementation of the VKM module at power plants brings the following benefits to the Customer:

- improving the ergonomic characteristics of the power plant control process;

- reducing the share of the “human factor”;

- improving the quality of management and economic performance of the generating company;

- together with EGSR, providing flexibility and the ability to select optimal equipment control modes.

It should be noted that, according to preliminary estimates, these works brought the Customer a positive economic effect with a payback period of no more than 3 years.

The system has been implemented since 2006 and has already been installed on 30 turbines in the region. Modernization of turbines and expansion of this system at stations in Tatarstan continues to this day.

Since the project is based on modern open computer technologies, it is also promising for implementation at power plants of the Republic of Kazakhstan.

We are currently developing a version of VKM, in the form of an independent system, capable of integrating into the station’s information systems and controlling electro-hydraulic control systems using unified interfaces and protocols.

Why is VKM connected to commercial meters with access to PBR information (balancing market plan). This solution will optimize the load on thermal mechanical equipment and minimize the need for the participation of the turbine operator in maintaining station power, which in turn will further increase the quality of generated electricity and the economics of the technological process.